United States

United States

December 14, 2025

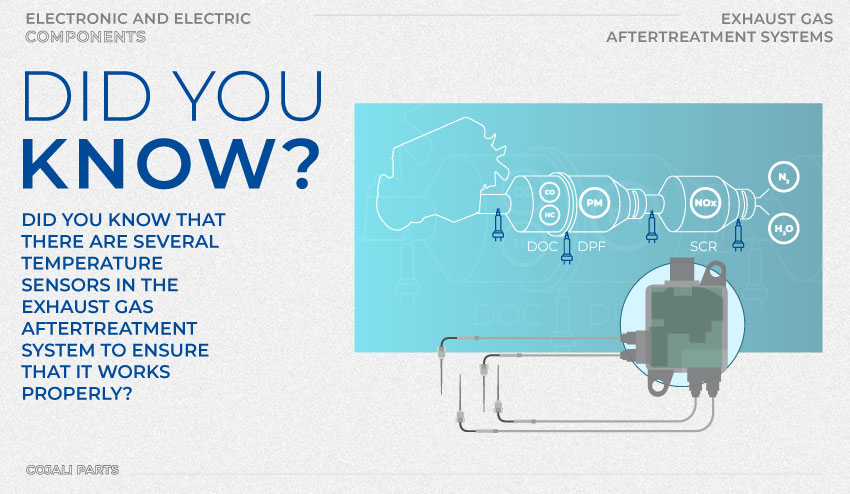

The aim of the aftertreatment system is reducing pollutant emissions by means of catalytic converters and filters.

These components - the oxidation catalytic converter (DOC), the particulate filter (DPF) and the selective catalytic reduction (SCR) - need to work within a very precise temperature range to be effective and to last.

Therefore, it is common to find 4 exhaust gas temperature (EGT) sensors distributed along the line:

1. Before DOC (pre-DOC): it measures the exhaust gas temperature at the system inlet, it protects the DOC and it serves as a reference for regeneration strategies.

2. Between DOC and DPF: it controls the temperature at the DPF inlet, ensuring the necessary heat for soot regeneration and preventing overheating.

3. After DPF: it checks the correct regeneration of the filter by temperature comparison and protects the DPF against thermal damage.

4. After SCR: it monitors the outlet temperature, ensuring efficient NOx reduction and acting as a final system control.

At Cojali we develop these sensors together with their control electronics, ensuring reliability, precision and compatibility.

COJALI S.L.

INFORMATION AND NEWS

DID YOU KNOW THAT THERE ARE SEVERAL TEMPERATURE SENSORS IN THE EXHAUST GAS AFTERTREATMENT SYSTEM TO ENSURE THAT IT WORKS PROPERLY?