United States

United States

December 14, 2025

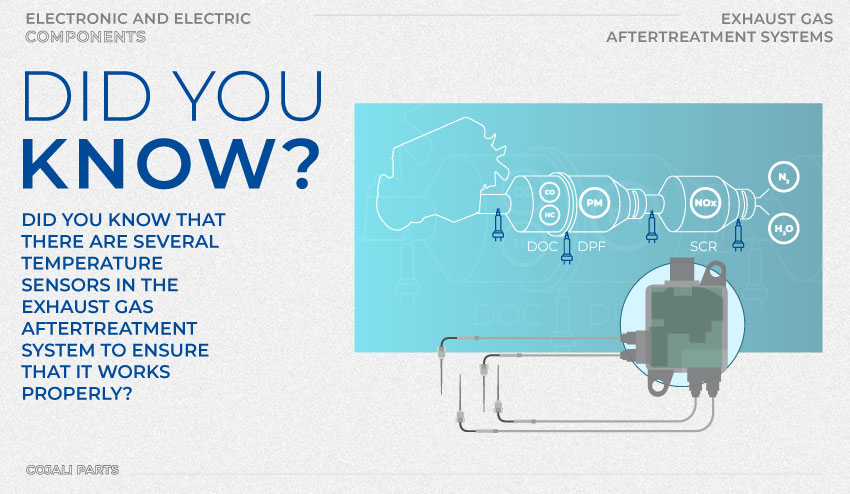

The aim of the aftertreatment system is reducing pollutant emissions by means of catalytic converters and filters.

These components - the oxidation catalytic converter (DOC), the particulate filter (DPF) and the selective catalytic reduction (SCR) - need to work within a very precise temperature range to be effective and to last.

Therefore, it is common to find 4 exhaust gas temperature (EGT) sensors distributed along the line:

1. Before DOC (pre-DOC): it measures the exhaust gas temperature at the system inlet, it protects the DOC and it serves as a reference for regeneration strategies.

2. Between DOC and DPF: it controls the temperature at the DPF inlet, ensuring the necessary heat for soot regeneration and preventing overheating.

3. After DPF: it checks the correct regeneration of the filter by temperature comparison and protects the DPF against thermal damage.

4. After SCR: it monitors the outlet temperature, ensuring efficient NOx reduction and acting as a final system control.

At Cojali we develop these sensors together with their control electronics, ensuring reliability, precision and compatibility.

COJALI S.L.

INFORMACE A ZPRÁVY

COJALI WILL BRING ITS TECHNOLOGICAL SOLUTIONS FOR COMMERCIAL VEHICLES TO ACMA AUTOMECHANIKA NEW DELHI 2026